Temperature Tamer: Using Shade Nets to Optimize Greenhouse Temperature

Introduction: The Greenhouse Paradox

Greenhouses are designed to trap solar energy, creating a warm environment ideal for cultivation, especially in cooler climates. However, in regions with intense sunlight or during hot summer months, this very function becomes a liability. The trapped heat can rapidly cause temperatures to soar beyond $40^circ C$ ($104^circ F$), leading to heat stress, flower abortion, and complete crop failure.

HDPE (High-Density Polyethylene) Shade Nets are the most effective and cost-efficient external solution for managing this heat risk. They serve as a sophisticated sun filter, reducing the incoming solar load to maintain the internal greenhouse temperature within the optimal range for plant growth.

This guide explores the scientific principles and practical techniques for using shade nets to optimize the temperature inside your greenhouse.

I. The Scientific Role of External Shading

Shade nets manage greenhouse temperature by addressing the two main drivers of heat buildup: solar radiation and heat retention.

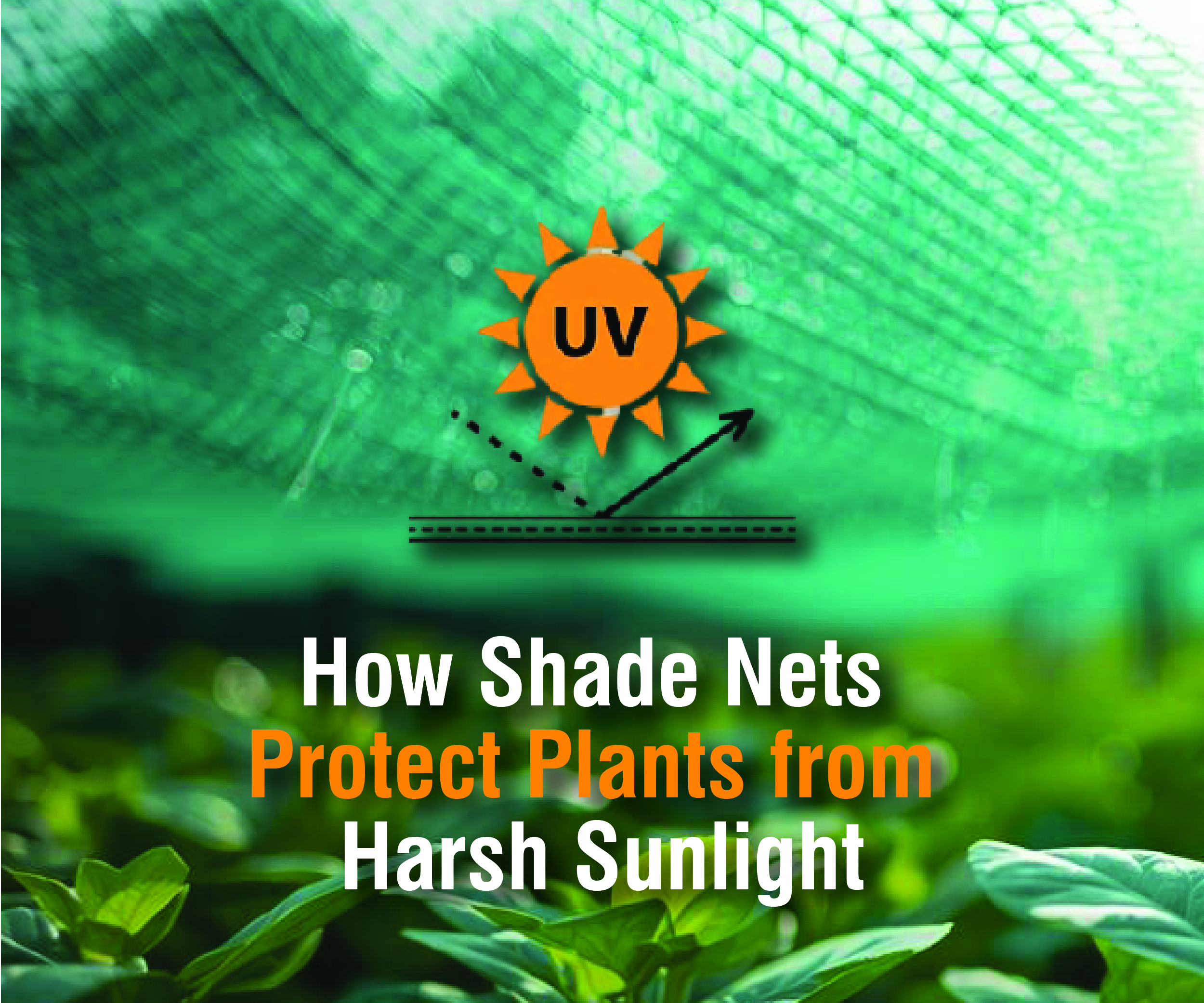

1. Blocking Solar Radiation (The Heat Source)

-

Radiation Reduction: An externally installed shade net, typically in the $30%$ to $50%$ range for most greenhouses, acts as the first line of defense. It intercepts a significant percentage of solar radiation before it passes through the plastic or glass roof.

-

Preventing Surface Heating: This radiation blockage prevents the internal surfaces (soil, benches, walls) from heating up excessively. These surfaces are the primary source of radiant heat that raises the air temperature inside the greenhouse.

-

Cooling Effect: By blocking the radiant energy, the shade net can effectively lower the internal ambient temperature by $5^circ C$ to $10^circ C$ compared to an unshaded greenhouse, bringing the environment back into the plant’s metabolic comfort zone.

2. Diffusing Light Quality

-

Stress Reduction: The net converts harsh, direct sunlight into diffused light. This soft light spreads more evenly across the leaves, reducing localized temperature spikes (hot spots) on the leaf surface.

-

Improved Photosynthesis: This diffused light is often utilized more efficiently by the lower leaves, boosting overall plant productivity without causing the stress associated with direct, intense light.

II. Key Techniques for Temperature Optimization

The effectiveness of a shade net depends on the material chosen and its method of deployment.

1. Choosing the Right Density

-

The Crop is Key: The density must be matched to the specific crop. A $30%$ net might be ideal for heat-sensitive fruiting crops like bell peppers in a moderate climate, while a $50%$ net might be necessary for cucumbers or propagation areas in a tropical climate. Too high a density ($75%+$) will cause ‘legginess’ (etiolation) and severely reduce fruiting.

-

The $5^circ C$ Rule: Start with the lightest shade net that achieves the required temperature reduction. For every 10% increase in shade density, expect a further marginal drop in temperature.

2. External vs. Internal Placement

| Placement | Temperature Control Benefit | Drawbacks |

| External (Recommended) | Superior. Blocks heat before it enters the structure. Better airflow keeps the net itself cooler. | Requires a stronger frame or cable system for installation. |

| Internal | Moderate. Trapped heat is reradiated inside, offering less overall cooling effect. | Easier to install and remove. Can be combined with thermal screens for energy saving at night. |

3. The Retractable System

-

Maximum Flexibility: The ideal solution for temperature optimization is a retractable external shade system (often motorized or pulley-operated).

-

Dynamic Control: This allows the net to be deployed only when needed (e.g., between 10 AM and 4 PM) and retracted on cloudy days or evenings. This maximizes natural light when temperatures are safe and provides cooling precisely when heat stress is highest.

III. Shade Net Integration with Other Systems

For complete temperature mastery, the shade net must work with the greenhouse’s existing infrastructure.

1. Ventilation Synergy

-

Heat Escape: No shade net can work effectively without proper ventilation. Ensure the greenhouse vents (roof and sides) are open when the net is deployed. The net keeps the air coming in cooler, and the open vents allow the hot air that still rises to escape.

-

Fan Systems: Use exhaust fans to actively pull hot air out, creating negative pressure. The shade net reduces the initial temperature of the incoming air, making the fan system much more efficient.

2. Water Management

-

Reduced Stress: Since the shade net reduces heat stress, the plants lose less water through transpiration, improving the efficiency of the drip irrigation system and reducing the need for fogging or misting systems.

IV. Conclusion

Shade nets are an indispensable tool for turning a seasonally challenging greenhouse into a year-round productive asset. By scientifically managing solar radiation, they lower the ambient temperature, reduce plant stress, and create the stable, optimal environment required for successful cultivation. Investing in a quality, correctly deployed shade net ensures that your greenhouse stays in the profit zone, even when the sun is at its most intense.

Frequently Asked Questions (FAQ)

Q1: Will a shade net reduce the need for cooling systems?

A: Yes. By significantly lowering the initial temperature, a shade net reduces the cooling load required by fans, misting, or pad systems. This leads to reduced energy consumption and lower operational costs for the cooling equipment.

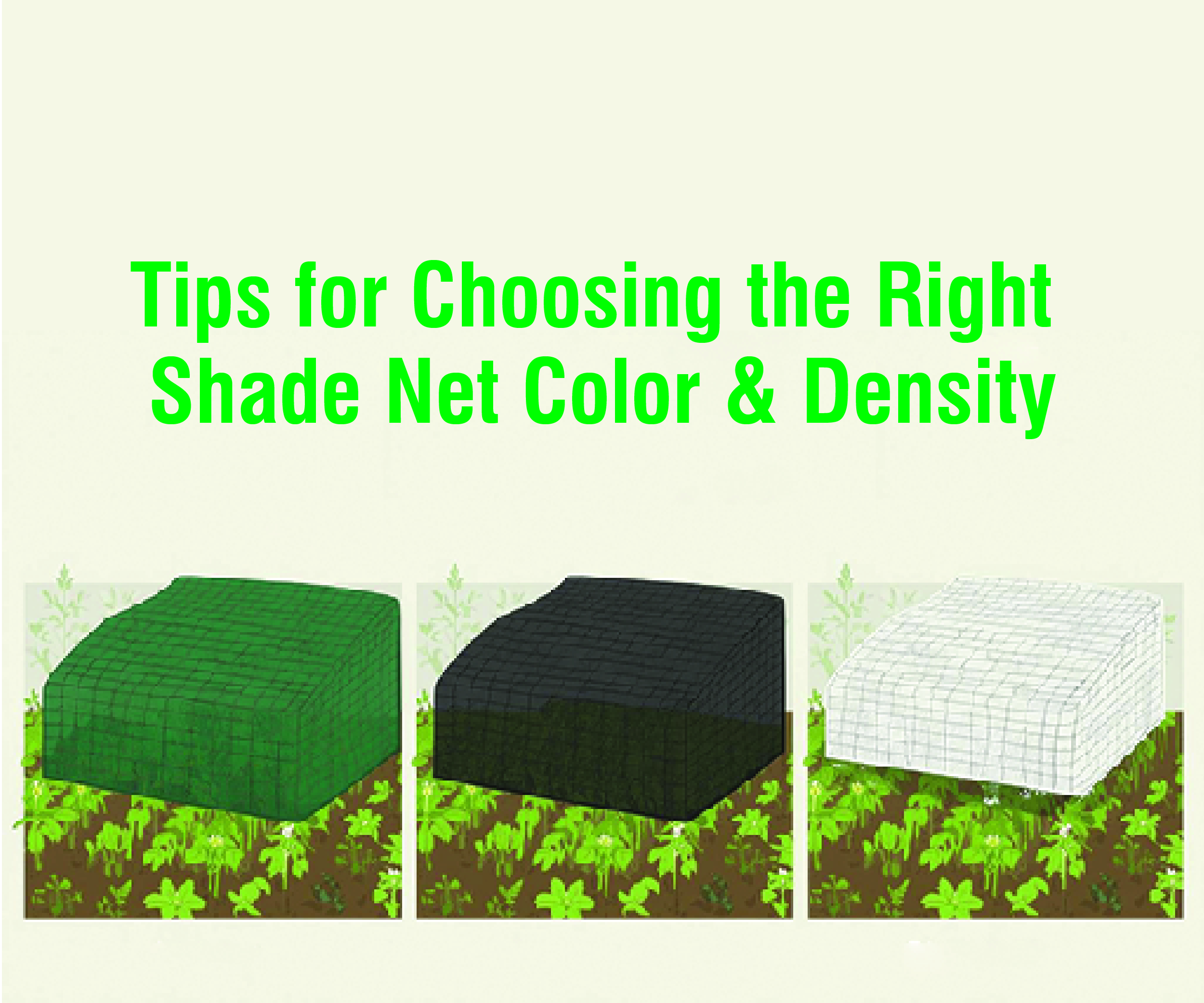

Q2: Does the color of the shade net matter for temperature optimization?

A: Yes. White or Pearl/Silver nets are often superior for temperature control because they reflect more solar energy away from the structure, leading to a cooler overall effect than black nets, which absorb the heat.

Q3: What are the risks of using a fixed (non-retractable) shade net?

A: The main risk is insufficient light on cloudy days or during the winter. Using a fixed net year-round can lead to etiolation (stretching, weak stems) and poor flowering when light levels are naturally low, potentially harming the crop.

Q4: Can a shade net alone solve my high temperature problems?

A: No. While highly effective, a shade net must be used in conjunction with adequate ventilation. It reduces the amount of heat entering, but ventilation (open vents, fans) is required to remove the heat that is still generated and to ensure fresh air circulation.