From Seed to Strong Sapling: How HDPE Nets Enhance Seedling Growth in Nurseries

Introduction: The Critical Nursery Stage

The nursery stage is arguably the most critical period in a plant’s life cycle. Healthy, vigorous seedlings are the foundation of a successful harvest. During this vulnerable time, seedlings face numerous threats, primarily from harsh weather, intense sunlight, and environmental stress.

High-Density Polyethylene (HDPE) Shade Nets have become indispensable tools for modern nursery management. These nets create a perfectly tailored microclimate, shielding the young plants while ensuring they receive the optimal balance of light, moisture, and temperature needed for robust and rapid growth.

This guide explores the scientific and practical ways in which HDPE nets enhance seedling growth, ensuring your saplings are strong, disease-resistant, and ready for successful transplantation.

I. Regulating the Microclimate: The Science of Shade

HDPE nets work by modifying the environment beneath them, solving three major problems faced by young plants.

1. Optimized Light Management

-

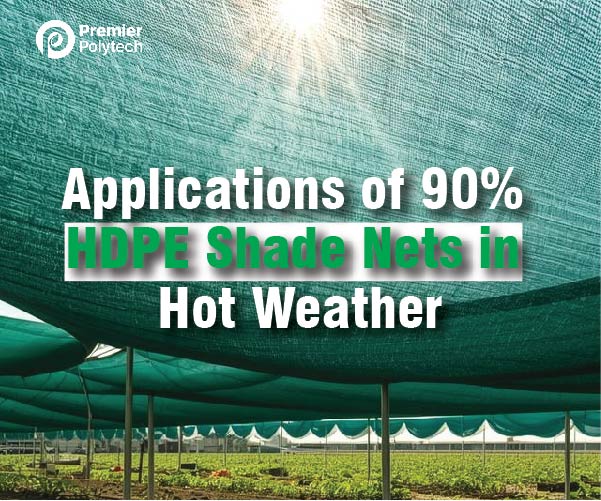

Preventing Photo-Oxidation: Intense, direct sunlight can cause “sunscald” or photo-oxidation, essentially burning the delicate leaves of young seedlings. HDPE nets, particularly those in the 50% to 75% range, filter the light, protecting the vulnerable plant tissue.

-

Diffused Light for Uniform Growth: The woven structure of the net scatters the light, converting harsh, direct rays into diffused light. This diffused light penetrates the entire canopy more evenly, promoting uniform photosynthesis across all leaves, rather than just the top layer. This results in bushier, healthier, and uniformly sized seedlings.

2. Temperature Mitigation

-

Cooling Effect: High ambient temperatures lead to excessive transpiration (water loss) in seedlings, causing dehydration and wilting. By blocking a significant portion of solar radiation, HDPE nets reduce the temperature inside the nursery by 5°C to 10°C (9°F to 18°F) during peak heat hours.

-

Reduced Heat Stress: This cooling effect minimizes heat stress, allowing the plants to divert energy from survival mechanisms to crucial growth processes like root development and leaf production.

3. Moisture and Humidity Control

-

Water Conservation: The reduced temperature under the shade net drastically lowers the rate of water evaporation from the soil and the plant surface. This translates to significant water savings and less frequent irrigation—a major cost-benefit for nurseries.

-

Stable Humidity: The netting helps maintain a more stable level of humidity, which is vital for new transplants and cuttings that have not yet established a strong root system capable of absorbing sufficient water from the soil.

II. Physical Protection and Structural Benefits

Beyond controlling light and heat, HDPE nets provide essential physical protection that contributes directly to seedling survival and quality.

1. Protection from Adverse Weather

-

Shield Against Rain and Hail: Heavy rainfall or hail can cause significant physical damage to delicate seedlings, breaking stems and tearing leaves. The netting breaks the velocity of raindrops, reducing their damaging impact and preventing soil splash, which can spread diseases.

-

Wind Protection: Strong winds cause plants to shake and dry out rapidly. The net acts as an effective windbreak, protecting the seedlings from mechanical damage and reducing excessive moisture loss.

2. Pest and Bird Exclusion

-

Physical Barrier: The density of the net acts as a basic physical barrier against larger pests like birds and rodents, which are notorious for damaging young nursery stock.

-

Reducing Chemical Reliance: By excluding larger threats, the nursery can reduce its reliance on chemical pesticides, leading to healthier, cleaner seedlings and lower operational costs.

3. Optimized Structure for Hardening

-

Phased Acclimatization: Farmers can strategically move seedlings from a high-shade area (e.g., $75%$ net) to a lower-shade area (e.g., $50%$ net) just before transplanting. This process, known as hardening off, prepares the seedlings for the full sun of the open field, minimizing post-transplant shock and ensuring higher survival rates.

III. Selecting the Right Net for Nursery Success

The ideal shade percentage in a nursery depends heavily on the crop being grown and the ambient temperature.

| Crop Type | Recommended Shade Percentage | Rationale |

| Vegetable Seedlings (Tomato, Cabbage) | 35% to 50% | Provides protection while ensuring enough light for rapid stem and leaf development. |

| Ornamentals & Cuttings (e.g., Carnation) | 50% to 75% | Requires moderate shade for better coloring and to promote root growth without stress. |

| Medicinal Plants & Ferns | 75% to 90% | Needs maximum shade as these are naturally low-light-loving plants. |

| Initial Seed Germination Area | 75% | High shade provides cool, stable conditions for the first few days of sprouting. |

Conclusion: The Foundation of a Flourishing Farm

HDPE shade nets are more than just a cover; they are a sophisticated climate management tool. By scientifically balancing light, temperature, and moisture, these nets transform a harsh environment into an ideal incubator, promoting superior root development, sturdy stems, and disease resistance in seedlings.

For any farmer, investing in a high-quality HDPE net for the nursery stage is the single most effective way to secure the foundation of their future harvest, ensuring successful transplantation and ultimately, higher yields and profitability.

Frequently Asked Questions (FAQ)

Q1: What is the most common mistake when using shade nets in a nursery?

A: The most common mistake is using a net with too high a shade percentage for the crop. Too much shade leads to “legginess” (etiolation)—tall, thin, weak stems that stretch for light. This results in poor seedlings that suffer severe transplant shock.

Q2: Does the color of the HDPE net matter for seedlings?

A: Yes, the color can affect the quality of light. Black provides maximum heat reduction and simple shade. Green nets allow for light that is often considered beneficial for vegetative growth. White nets reflect more heat and diffuse light more widely, often preferred in very hot, arid regions.

Q3: Should I remove the net on cloudy or rainy days?

A: Generally, no. The shade net is part of the permanent structure, providing protection from wind and large rain drops. Removing and reinstalling it frequently causes wear and tear. Only if you notice the seedlings are struggling due to severely low light for prolonged periods should you consider partial removal.

Q4: How important is ventilation in a shade net nursery setup?

A: Extremely important. While the net provides shade, good ventilation (i.e., open sides or tall structures) is essential to prevent heat buildup and high humidity, which can promote fungal and bacterial diseases like damping-off. The net must be installed correctly to allow free airflow.