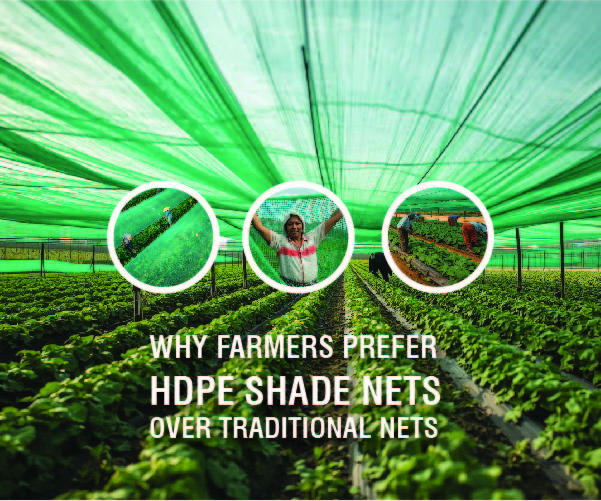

Why Farmers Are Switching to HDPE Shade Nets: A Comprehensive Guide

Introduction: The Evolution of Crop Protection

Farmers have always relied on various methods to protect their crops from harsh weather, pests, and excessive sunlight. For generations, traditional netting materials like jute, coir, or loosely woven fabrics served this purpose. However, with advances in material science, a far more efficient and durable solution has emerged: High-Density Polyethylene (HDPE) shade nets.

HDPE shade nets offer a significant upgrade, providing precision climate control and vastly improved longevity. This shift is not just a trend; it’s an economic and environmental necessity for modern, sustainable farming. This guide will explore the reasons why farmers prefer HDPE nets and how they contribute to better yields and resource management.

What is an HDPE Shade Net?

HDPE shade nets are specialized nets made from High-Density Polyethylene material. This plastic polymer is woven or knitted into a mesh structure.

Key Characteristics of HDPE:

- High Strength-to-Density Ratio: It is very strong yet lightweight.

- UV Stabilization: Crucially, these nets are treated with UV stabilizers, allowing them to withstand prolonged exposure to intense sunlight without degrading.

- Chemical Inertness: They resist breakdown from common agricultural chemicals and fertilizers.

- Durability: HDPE nets can last for many years, often exceeding 5 to 7 seasons.

HDPE vs. Traditional Nets: The Key Differences

The preference for HDPE nets stems from a direct comparison with older, natural, or less-durable synthetic materials.

| Feature | HDPE Shade Nets | Traditional Nets (Jute, Coir, etc.) |

| Material | UV-stabilized High-Density Polyethylene | Natural fibers (Jute, Coir, Cotton) or low-grade synthetics |

| Durability/Lifespan | 5+ Years (Highly resistant to tearing and degradation) | 1-2 Seasons (Prone to rot, mildew, and UV damage) |

| Shade Factor Control | Available in precise shading percentages (e.g., 35%, 50%, 75%) | Varies widely, often inconsistent |

| Weight | Lightweight and easy to install/handle | Heavier, especially when wet |

| Water & Chemical Resistance | Excellent (No rotting or mildew) | Poor (Absorbs water, leading to decomposition) |

| Pest Control | Fine, uniform mesh acts as an excellent physical barrier | Looser weaves may not effectively block smaller insects |

| Cost Over Time | Higher initial cost, but lower long-term cost | Lower initial cost, but high recurring replacement costs |

Economic Benefits: Enhancing ROI and Sustainability

The main reason for the widespread adoption of HDPE nets is their significant economic return on investment (ROI).

1. Improved Crop Yield and Quality

HDPE nets allow farmers to precisely control the amount of sunlight reaching the crop. This optimal light filtration prevents sun-scald and heat stress, leading to:

- Healthier plant growth and reduced flower/fruit drop.

- Increased marketable yield.

- Improved fruit size, color, and texture, demanding a better market price.

2. Water Conservation

By reducing direct solar radiation and wind speed inside the shaded area, the nets significantly reduce the rate of water evaporation from the soil and transpiration from the plants. This translates directly into substantial savings on irrigation water—a crucial factor in drought-prone or water-scarce regions.

3. Exceptional Longevity and Durability

The investment in HDPE is justified by its long life. Where traditional nets might need replacement every year, a quality HDPE net can last for five years or more. This drastically reduces annual material and labor costs associated with installation and removal. The material’s resistance to tearing, wind damage, and pests further ensures minimal maintenance.

Functional Advantages: Protecting Crops and Resources

Beyond economics, the functional performance of HDPE nets provides critical protection.

1. Precise Climate and Light Management

Different crops require different light intensities. HDPE nets are available in a variety of shade factors, typically ranging from 25% for leafy vegetables to 90% for covering nurseries. This ability to tailor the microclimate is essential for growing high-value crops like orchids, strawberries, and exotic vegetables.

2. Protection Against Weather Extremes

HDPE nets act as a shield against unpredictable weather:

- Hail and Storm Damage: The woven structure can absorb the impact of hail and heavy rain, preventing physical damage to delicate crops.

- Windbreak: They significantly slow down wind velocity, which reduces physical plant damage and excessive moisture loss.

- Frost Protection: The net can trap a layer of warm air near the plants, offering a degree of protection against mild frost.

3. Pest and Bird Control

The nets serve as a highly effective physical barrier, preventing birds from consuming fruits and reducing the entry of large insects and pests, thereby minimizing the need for expensive and potentially harmful pesticides.

Environmental and Health Benefits

The environmental footprint of modern farming is a growing concern. HDPE nets help address this through sustainable practices.

- Reduced Chemical Use: By controlling pests and diseases through climate regulation and physical barriers, farmers can rely less on chemical sprays.

- Enhanced Water Security: The massive savings in irrigation water contribute to regional water table preservation.

- Sustainable Material Use (Long-Term): While HDPE is a plastic, its multi-year lifespan means less material is consumed and discarded compared to yearly replacements of traditional nets. Furthermore, most HDPE nets are now manufactured to be fully recyclable at the end of their service life.

How to Choose the Right HDPE Shade Net

Selecting the correct net is crucial for maximizing benefits. Farmers should consider three main factors:

- Shade Factor: Match the percentage to the crop’s light requirements. High-light crops need lower shade percentages (e.g., 35%); shade-loving crops need higher (e.g., 75%).

- Color:

- Black: Provides direct light reduction and heat absorption, common for general use.

- Green: Preferred for nurseries and ornamental plants, offering a natural visual spectrum.

- White/Pearl: Reflects heat, keeping the area cooler, often used in hot climates.

- Knitting Density (GSM): A higher GSM (Grams per Square Meter) generally indicates a stronger, more durable net with a tighter weave.

Conclusion: Securing the Future of Farming

The preference for HDPE shade nets over traditional materials is a clear indicator of the progress in agricultural technology. Their ability to deliver precise environmental control, exceptional durability, and significant economic savings makes them an indispensable tool for the modern farmer. By adopting HDPE nets, growers are not only improving their bottom line but also contributing to more efficient, sustainable, and high-yield farming practices that can better meet the demands of a growing global population.

Frequently Asked Questions (FAQ) – SEO Optimized

Q1: What is the main difference between green and black shade nets?

A: Black nets reduce light but can absorb more heat, generally used for general shading. Green nets filter light to a spectrum that is often preferred by nurseries and ornamental plants, promoting photosynthesis while reducing harsh light. White or Pearl nets reflect light and heat, offering the best cooling effect.

Q2: How long does an HDPE shade net typically last?

A: High-quality, UV-stabilized HDPE shade nets typically last 5 to 7 years or sometimes even longer under normal conditions. Their lifespan far exceeds that of traditional nets, which often degrade in a single season due to UV exposure, rot, and mildew.

Q3: Are HDPE nets recyclable?

A: Yes, most modern HDPE nets are 100% recyclable at the end of their useful life. HDPE (High-Density Polyethylene) is a widely recycled plastic, making it a more environmentally sound choice in the long run compared to non-recyclable synthetics.

Q4: How do I choose the right shade percentage for my crop?

A: The required shade percentage depends entirely on the crop.

- Low Shade (25%-35%): For vegetables like tomatoes, peppers, and most field crops.

- Medium Shade (45%-65%): For shade-loving vegetables, ornamental plants, and flowers.

- High Shade (75%-90%): For delicate nursery plants, tissue culture hardening, and orchids.

Q5: Can HDPE shade nets protect against rain?

A: HDPE shade nets are porous, so they allow water and air to pass through. While they protect against the impact of heavy rain and hail, they are not waterproof. For full rain protection, a farmer would need to use a poly-film or a specialized waterproof shade cloth.